Creating the Future with Digitalization

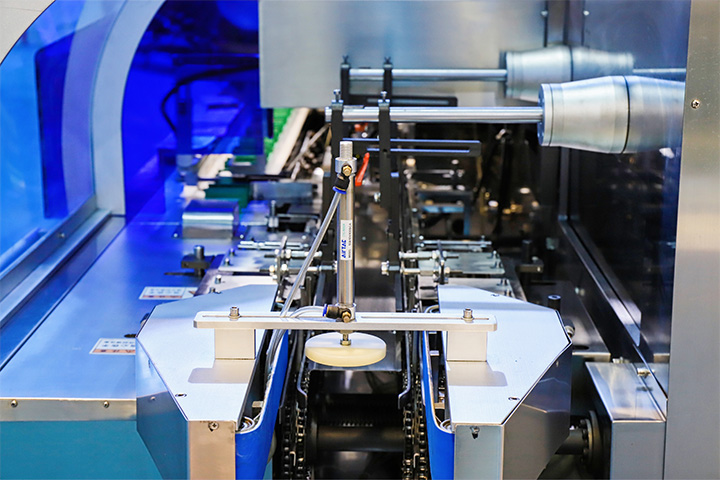

The 2023 China · Qingdao International Digital Factory Exhibition will take factory information products and technologies, intelligent production equipment and systems as the main display sections, and will present a high-quality professional exhibition for exhibitors and visitors.

This exhibition will attract high-end buyers of various manufacturing enterprises from more than 20 countries and regions at home and abroad, covering electronic information, mechanical equipment, automobile manufacturing, energy industry, hardware and mechatronics, iron and steel metallurgy, food and beverage, medical and health care, and other fields.

By participating in the exhibition, exhibitors can easily and efficiently obtain sales leads, promote new products, and establish a brand image to further enhance their market competitiveness.

2023 China · Qingdao International Digital Factory Exhibition will fully display the production, management equipment and systems of digital factories to help you seize business opportunities under the new development pattern of "dual circulation".

-

At present, the transformation and upgrading of intelligent manufacturing has become an inevitable trend. Through investment in new technologies such as the Internet of Things, cloud computing, and big data, it can improve enterprise performance, reduce manufacturing costs, and allow enterprises to quickly adapt to changing market needs.

-

In the whole process of enterprise operation, a simulated 3D model can be established, and through simulated operation, performance monitoring and fault diagnosis can be carried out in stages ranging from landing gear to a factory, product design, production operation, packaging and logistics, etc. Even in the development stage, defects can be found and corrected in time, improving accuracy and avoiding rework after completion.

-

The future manufacturing industry is the integration of automation and IT platforms, artificial intelligence and energy technologies. The new model of digital factories, whether in production data collection or production operation management, will replace traditional factories and demonstrate their advantages.

-

The virtual design and verification of products are conveniently carried out through digital factory technology, which minimizes the production and modification of physical prototypes, thereby effectively reducing resource waste and product development costs. At the same time, make full use of the existing data (customer demand, production raw materials, equipment status, etc.) to carry out production simulation and prediction, make pre-judgment and decision-making on the production process, so as to improve production income and capital utilization efficiency.

-

什么是数字化工厂?如何才能打造一个真正的数字化工厂2021-04-09近年来,随着科技的发展,数字化工厂的打造成为了很多企业的重要战略目标。那么如何打造数字化工厂成为了首要问题。 近期,普华永道思略特合伙人夷萍分析了数字化工厂的四个核心特点:产品的智能化、生产的自动化、信息流和物资流合一,提供了数字化工厂的打造方式和成功蓝图。

-

数字化工厂的打造有别于传统业务模式2021-04-14数字化可以让制造型企业从根本上改头换面。数字化工厂的核心特点是:产品的智能化、生产的自动化、信息流和物资流合一。

-

中国制造的数字化转型2021-04-14德国“工业4.0”、美国“第三次工业革命”、中国“制造业2025”,世界各国纷纷提出新一代制造理念,主要是为了指导工业制造业的发展,在数字化、智能化、网络化的全球大环境下,拉动传统制造往智能制造方向升级,从而满足未来市场更快速、更个性化的需求响应,并实现更低的制造成本(见图“工业4.0 的演进过程”)。

-

数字化工厂转型之中的四大挑战2021-04-15中国数字化工厂的蓬勃发展固然可喜,但我们也发现了一些问题。当我们与希望建设数字化工厂的客户接洽时,通常能听到他们表示:“我们想造一座类似于某企业的全自动工厂或‘智能化’工厂。”而我们接下来抛出的问题自然是“贵公司如何定义‘智能化’?是否有清晰的数字化工厂战略?是否有明确的各项评估指?”然而,大多数企业并不能明确阐述他们希望中的数字化工厂,而是寄希望于有现成的智能化工厂定义,能够毫不费力地直接照搬。在我们看来,数字化工厂的定义以及对成功的评判指标建立在多种因素之上。